VENTORA - EAST

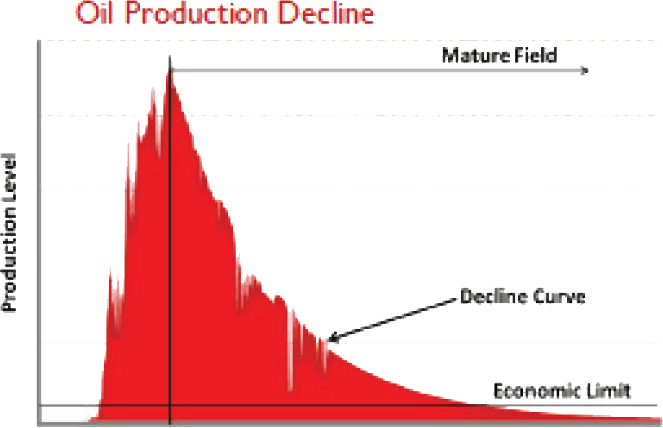

Declining oil production from existing wells is a consistent problem for oil companies. Most oil wells experience a steep production decline curve as a result of physical, chemical, and bacteriological factors producing what is called "Skin Damage".

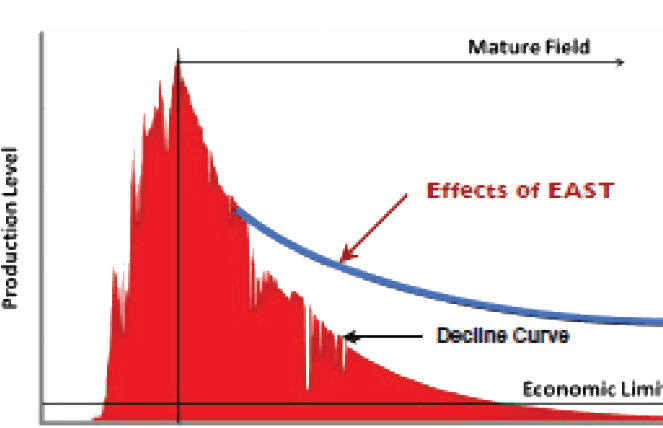

Ventora - EAST is an innovative and proven physical stimulation technology that is a cost-effective solution to cure formation damage and enhance oil production rates or injectivity in disposal and injector wells.

The Problem (Skin Damage)

- • Containment & Higher viscosity

- • Reduced permeability

- • Fines and scale deposits

- • Paraffin and asphaltene plugging

- • Increased surface tension in capillaries

The Solution (Benefits)

- Enhancement of oil flow

- Removal of wax and asphaltene deposits

- Reduction of surface tension & viscosity

- Decontamination & unclogging particles

- Improvement of liquid penetration

Proven Efficiency

Early field trials called efficiency improvements have become the hallmark of establishing Ventora as the world leader, providing a simple, fast, repeatable, and highly efficient treatment with a high success rate.

Technology Evolution & Efficiency

| Parameter | Until 2015 | 2016 | 2018 (Latest) |

|---|---|---|---|

| Tool Oscillation Zone | 0.3 meter | 1 meter | 2.5 - 7.5 meter |

| Tool OD | 42 mm | 44 mm | 51 mm |

| Output Power | 0.6 kW | 1.2 kW | 4.5 kW |

| Treatment / 12h | 4 meters | 24 meters | 60 - 180 meters |

| Well Type | Vertical | Vertical | Vertical & Horizontal |